Izinto ezincane zivame ukungcolile ngesikhathi sokugcinwa kanye nokuhamba, futhi izinto eziningi zivame ukuhlanganiswa ndawonye ngokuvumelana nemithetho ethile. Ukupakishwa kwebhokisi elihlanganisiwe le-pre roll libhekisela ekuqoqweni kwezingcezu eziningi ezincane zezimpahla ezipakishiwe noma ezingapakishiwe zibe yiyunithi enkulu yempahla engakhushulwa noma ifakwe ngemfoloko ngesiqukathi ukuze kube lula ukusetshenziswa kwemishini yokulayisha, ukuthulula kanye nokusingatha imisebenzi. Iziqukathi zingahlukaniswa cishe zibe izigaba eziyisithupha ngokobumo bazo: iziqukathi ezihlanganisiwe, iziqukathi zephalethi, izikhwama zeziqukathi, amanetha ezitsha nezitsha. Inhloso yokupakishwa kweziqukathi ukusindisa abasebenzi kanye nokunciphisa ezokuthutha kanyeibhokisi lokubonisa langaphambiliizindleko zokupakisha zezimpahla.

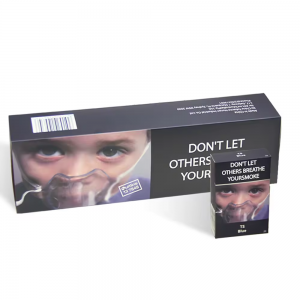

Ibhokisi lokubonisa langaphambiliindlela yokupakisha

Ukuhlanganisa nokufaka iziqukathi kuyindlela yokuhlanganisa yokupakisha esebenzisa izinto zokubopha ukuze kuhlanganiswe izimpahla ezifana nemikhiqizo yensimbi, ukhuni, noma amaphakheji amancane kube iyunithi yokuthutha idatha ezimele. Umdwebo 7-17 ubonisa ukusetshenziswa kwebhande elihlukahlukene kanye nokufaka iziqukathi. Lokhu ukupakishaibhokisi lokubonisa langaphambiliinqubo idla izinto zokupakisha ezincane, inezindleko eziphansi, kulula ukuyigcina, ukulayishwa, ukulayishwa, kanye nokuthutha, futhi inemisebenzi yokuvala, yokuvala, yokulwa nokweba, kanye nokuvimbela izinto ukuthi zingalahleki noma zibhidlike.

Izinto ezisetshenziswa kakhulu zokubophaibhokisi lokubonisa langaphambili

Izinto ezisetshenziswa kakhulu zokubopha zihlanganisa izintambo zensimbi, izintambo zensimbi, i-polyester, inayiloni, i-polyethylene, i-polypropylene, i-polyvinyl chloride nezinye izintambo zokubopha epulasitiki kanye nezintambo zokubopha eziqinisiwe. Intambo yensimbi isetshenziswa kakhulu ukuhlanganisa izinto eziqinile njengamaphrofayili ensimbi, amapayipi, izitini, amabhokisi okhuni, njll. Lapho uhlanganisa amabhokisi okhuni, azoshunyekwa emaphethelweni nasemakhoneni amabhokisi okhuni. Izintambo zensimbi ziwuhlobo lwebhande elinamandla aqine kakhulu. Zinezinga elincane lokunweba futhi ngokuyisisekelo azithintwa izici ezifana nokukhanya kwelanga nezinga lokushisa. Zinamandla amahle kakhulu okugcina ukushuba kwesimo futhi zingamelana nokuqina kwezimpahla ezicindezelwe zamandla aphezulu, kodwa zijwayele ukugqwala. Amabhande e-polyester anamandla aphezulu okuqinile kanye nokumelana nomthelela, izakhiwo ezinhle zokululama ezinwebekayo namandla okugcina ukushuba, ukumelana namakhemikhali okuhle, kanye nokugcinwa okuhle kwesikhathi eside. Angakwazi ukufaka amabhande ensimbi esikhundleni sokupakishaibhokisi lokubonisa langaphambiliizinto ezinzima. Amabhande enayiloni ayanwebeka, aqinile, anokumelana nokugqokwa okuhle, ukumelana nokugoba, ukumelana namanzi, ukumelana namakhemikhali, futhi anesisindo esincane. Ngokuyinhloko zisetshenziselwa ukuhlanganisa nokupakisha izinto ezinzima, ama-pallets, njll. Izintambo ze-polyethylene ziyizinto ezinhle kakhulu zokubopha imisebenzi yezandla. Ziyakwazi ukumelana namanzi futhi zifanele ukubopha imikhiqizo yezolimo enomswakama ophezulu. Bangakwazi ukugcina umumo othembekile futhi ozinzile, uzinzile endaweni yokugcina, futhi kulula ukuyisebenzisa. Ibhande le-polypropylene lilula futhi lithambile, linamandla aphezulu, alikwazi ukumelana namanzi.

Iphalethi iyisisetshenziswa sesitsha esisetshenziselwa ukupakisha izimpahla ngendlela ethile futhi ingalayishwa, yehliswe futhi ihanjiswe. Ukupakishwa kwephalethiibhokisi lokubonisa langaphambilikuyindlela yokuhlanganisa ehlanganisa amaphakheji noma izimpahla eziningana zibe iyunithi yokusingatha ezimele ngendlela ethile. Ilungele ukulayisha nokuthulula ngemishini imisebenzi yokuthutha, isiza ukuphathwa kwempahla yesimanje, futhi ingathuthukisa kakhulu ukulayisha nokuthulula kanye nokuhamba kahle kwezimpahla. Izinga lokuphatha indawo yokugcina impahla.

1. Ibhokisi lokubonisa langaphambiliinqubo yokupakisha ye-pallet

(1) Ukupakishwa kwephalethiibhokisi lokubonisa langaphambilinezici zayo Izinzuzo zokupakishwa kwe-pallet zisebenza kahle jikelele, ukupakisha okubushelelezi futhi okuzinzile, okungagwema ukwenzeka kwamaphakheji awela emabhokisini ngesikhathi sokugcina, ukulayisha, ukuthulula, ukuthutha kanye nezinye izinqubo zokujikeleza. Ilungele ukulayisha, ukuthulula kanye nokuthuthwa kwemishini emikhulu. Uma kuqhathaniswa nokuthembela kubasebenzi kanye nemishini emincane ukulayisha nokukhipha amaphakheji amancane, ukusebenza kahle kwawo kungathuthukiswa kakhulu, futhi kunganciphisa kakhulu amathuba okushayisana, ukuwa, ukulahlwa kanye nokuphathwa kabi kwezimpahla ngesikhathi sokugcinwa, ukulayishwa nokuthulula, ukuthuthwa kanye nezinye izinqubo zokujikeleza, ukuqinisekisa Ukuvikeleka kokushintshwa kwempahla. Kodwa-ke, ukupakishwa kwe-pallet kwandisa izindleko zokukhiqizwa nokugcinwa kwe-pallet, futhi kudinga ukuthengwa kwemishini yokuphatha ehambisanayo. Izibalo ezifanele zibonisa ukuthi ukusebenzisa ukupakishwa kwephalethiibhokisi lokubonisa langaphambiliesikhundleni sokupakishwa kwasekuqaleni kunganciphisa kakhulu izindleko zokujikeleza, okuhlanganisa ukuncishiswa kuka-45% kwezinto zikagesi zasendlini, ukuncishiswa ngo-60% emikhiqizweni yephepha, ukuncishiswa ngo-55% kwegrosa, kanye nokwehliswa ngo-15% kwengilazi eyisicaba nezitini eziqinile.

(2) Izindlela zokunqwabelanisa i-pallet Ngokuvamile kunezindlela ezine zokupakishwa kwephalethi, okuwuhlobo lokubuka kabusha olulula, uhlobo oluyaluzayo noluhlehlayo, uhlobo lwe-crisscross kanye nokupakishwa kohlobo oluyaluzayo oluzungezayo, njengoba kukhonjisiwe kuMfanekiso 7-18. Izindlela ezihlukene zokupakisha zinezinzuzo zazo kanye nokubi, okufanele zikhethwe ngokuya ngesimo esithile.

Ngokunqwabelanisa okulula okugqagqene, izimpahla kungqimba ngalunye zihlelwa ngendlela efanayo, kodwa akukho ukunqwabelana. Izimpahla zivame ukuhlukaniswa kalula ngobude, azinzinzi kahle, futhi zidinga amandla acindezelayo aphezulu ongqimba olungezansi lwezimpahla. Ngokombono wokuthuthukisa ukusebenza kahle kokunqwabelanisa kanye nokunikeza ukudlala okuphelele kumandla acindezelayo okupakisha, ukunqwabelanisa okulula kuyindlela engcono kakhulu yokupakisha. Amaphethini okustakika wezendlalelo ezinenombolo engavamile kanye nezendlalelo ezinenombolo elinganayo zokupakisha okuya phambili nokuhlehlayo kuhluke ngo-180°. Ukugqagqana phakathi kwezingqimba kuhle, futhi ukuzinza kwempahla ye-pallet kuphezulu. Le ndlela yokunqwabelanisa isetshenziswa kakhulu kumaphalethi awunxande, kanti ubude nobubanzi bempahla yi-I ratio ngu-3:2 noma 6:5. Izendlalelo eziyinqaba nezinezinombolo ze-criss-cross stacking zipakishwe ezindaweni ezihlukene. Izikhombisi-ndlela zamaphethini wokupakisha wezendlalelo ezimbili eziseduze zihluka ngo-90°. Isetshenziselwa ikakhulukazi ama-pallets ayisikwele. Ku-stacking staggered, lapho kupakishwa ungqimba ngalunye, isiqondiso sishintshwa ngo-90 ° ukuze kwakhiwe ukugqagqana ukuze kuqinisekiswe ukuzinza, kodwa ngenxa yokuthi isikhungo sithambekele emigodini, kunciphisa ukusetshenziswa kwendawo ye-pallet, le ndlela yokupakisha isetshenziselwa ikakhulukazi ama-pallets ayizikwele. Ukuze kuqinisekiswe isayensi nokuphepha kokupakisha izimpahla kuma-pallets ngendlela ethile, lapho uklama ukupakishwa kwephalethi, kuyadingeka ukuthi ubhekisele kuzinga likazwelonke le-CB4892 “Rigid Cuboid Transport Packaging Dimension Series” okusekelwe ohlotsheni lwezimpahla, ubukhulu bephalethi nosayizi, njll. “I-Bag Transportation Packaging Dimension Series” kanye namanye amazinga okunquma ngokunengqondo indlela yokunqwabelanisa yezimpahla kuphalethi, futhi izinga lokusebenzisa i-pallet surface ngokuvamile alikho ngaphansi kuka-80%.

Izimiso eziyisisekelo zokukhetha izindlela zokupakisha i-pallet yilezi:

① Izimpahla eziqinile eziwunxande njengeziqukathi zokhuni, zephepha nezensimbi kufanele zipakishwe ngendlela eyodwa noma enezendlalelo eziningi futhi zihlanganiswe nokupakishwa okunwetshiwe noma okushwabanisayo; ② Izimpahla zephepha noma zefayibha Sebenzisa ukupakishwa okukodwa noma okunezendlalelo eziningi nokubeka uphawu oluphambanayo nge-strapping tape; ③ Iziqukathi zensimbi ezivaliwe nezinye izimpahla eziyisilinda kufanele zipakishwe ngesitayela esisodwa noma esinezingqimba eziningi futhi ziqiniswe ngamakhava okhuni; ④ Ivikela umswakama, ingangeni manzi, njll. Imikhiqizo yephepha elivikelayo nezindwangu kufanele kupakishwe izendlalelo eziningi futhi inyakaze, futhi isebenzise ukupakishwa okunwebekayo, ukushwabanisa ukupakisha noma ukwengeza izisekelo zamakhona, amakhava nezinye izakhiwo zokuqinisa; ⑤ Izimpahla ezintekenteke kufanele zipakishwe ngezingqimba eyodwa noma eziningi, nezisekelo zokhuni zengezwe Isakhiwo sokuhlukanisa; ⑥ Iziqukathi zebhodlela lensimbi eziyisilinda noma izimpahla zipakishwa ngokuqondile kusendlalelo esisodwa ukuze zande.

Isakhiwo siqiniswa ngamafreyimu wezimpahla kanye nama-slats; ⑦ Izikhwama zezimpahla isikhathi esiningi zipakishwa ngendlela eya phambili nehlehlayo ediyazela. Emaphaketheni e-pallet, umkhiqizo wokupakisha ongezansi uthwala umthwalo ocindezelayo wezimpahla ezingaphezulu, futhi izimo zokucindezela isikhathi eside zizokwenza ukuthi isitsha sokupakisha noma izinto ezibonakalayo zikhase, okuthinta ukuzinza kwephalethi. Ngakho-ke, lapho uklama ukupakishwa kwe-pallet, kuyadingeka ukuthi uhlole amandla okupakisha eziqukathi zokupakisha futhi ucabangele izakhiwo ezinyakazayo zeziqukathi zokupakisha noma izinto zokupakisha ukuze kuqinisekiswe ukuphepha kwempahla ngesikhathi sokugcina nokuhamba.

(3) Indlela yokulungisa i-pallet Ngesikhathi sokugcina kanye nenqubo yokuthutha yezimpahla zeyunithi ezilayishwe i-pallet, ukuze kuqinisekiswe ukuzinza kwayo, izindlela ezifanele zokubopha kufanele zisetshenziswe ukuvimbela ukuba zingawi. Ngemikhiqizo edinga izidingo zokuvikela umswakama nokungangeni kwamanzi, izinyathelo ezihambisanayo kufanele zithathwe. Izindlela zokulungisa ezivame ukusetshenziswa zokupakisha i-palletibhokisi lokubonisa langaphambilizihlanganisa ukuhlanganisa, ukunamathisela, ukugoqa, kanye nezinsiza zokuqinisa ezivikelayo, njll., ezingasetshenziswa futhi ngokuhambisana. Izindlela zokuhlanganisa nokubopha ngokuvamile zisebenzisa izintambo zensimbi nezintambo zepulasitiki ukuze zibophe amaphakheji namaphalethi avundlile naqondile ukuze kuvinjelwe imikhiqizo epakishiwe ukuthi inganyakazi ngesikhathi sokuthutha. () (e) Njengoba kuboniswe kuMfanekiso 7-19, indlela yokulungisa i-pallet ehlukahlukene. Okokufaka kwephalethi okungakakwazi ukuhlangabezana nephakheji yezokuthuthaibhokisi lokubonisa langaphambiliizidingo ngemuva kokulungiswa, izesekeli zokuqinisa ezivikelayo kufanele zikhethwe njengoba kudingeka. Izesekeli zokuqinisa ezivikelayo zenziwe ngephepha, ipulasitiki yokhuni, insimbi noma ezinye izinto.

2.Ibhokisi lokubonisa langaphambiliPallet Packaging design indlela

Usayizi wamaphalethi umisiwe. Ukuze uqinisekise umphumela wokupakishwa kwe-pallet, ibhokisi lokupakisha lemikhiqizo kufanele lihlanganiswe ngokunengqondo. Izinga lokupakishwa kwe-pallet lithinta ngqo ukuphepha kwemikhiqizo ehlanganisiwe ohlelweni lokujikeleza. Ukupakishwa kwe-pallet okunengqondo kungathuthukisa ikhwalithi yokupakisha nokuphepha, kusheshise ukuhanjiswa, futhi kunciphise izindleko zokuhamba nokupakisha. Kunezindlela ezimbili zokuklama zokupakishwa kwe-pallet: "ngaphakathi-ngaphandle" kanye "ngaphandle-ngaphakathi".

(1) Indlela yokuklama “yangaphakathi-ngaphandle” iwukuklama ukupakishwa kwangaphakathi, ukupakisha kwangaphandle kanye nephalethi ngokulandelana ngokuya ngosayizi wesakhiwo somkhiqizo. Umkhiqizo upakishwa waba amaphakheji amancane ngokulandelana ukusuka ku-workshop yokukhiqiza, bese ngokuya ngamaphakheji amancane amaningi noma osayizi abakhulu Khetha amabhokisi okupakisha asekelwe ekufakweni ngakunye.ibhokisi lokubonisa langaphambili, bese uhlanganisa amabhokisi okupakisha akhethiwe kuma-pallet, bese uwahambisa kubasebenzisi. Inqubo yokuklama iboniswa kuMfanekiso 7-20. Ngokusho kobukhulu bephakheji yangaphandle, indlela ebekwe ngayo ku-pallet inganqunywa. Njengoba kunezindlela eziningi zokupakisha amabhokisi kathayela wesayizi ethile endizeni ye-pallet, kuyadingeka ukuqhathanisa izindlela ezahlukahlukene bese ukhetha isisombululo esifanele.

Lapho uklama ukupakishwa kwe-pallet, i-modulus yokupakisha eyaziwa emhlabeni wonke ye-cuboid eqinile [600, 400] kufanele ilandelwe, futhi ubukhulu [1200, 800] kanye [12001000] ku-GB2934 ejwayelekile "Ubukhulu obukhulu kanye nokubekezelelana kwe-Universal Flallet okuncanyelwayo" kufanele kube yi-Intermotred Pallet. Ama-pallet ochungechunge ukuze asebenzise ngokugcwele indawo engaphezulu ye-pallet futhi anciphise izindleko zokupakisha nezokuthutha. Idizayini yokupakisha ye-pallet enevolumu enkulu ingaqedelwa kusetshenziswa isofthiwe yokuklama yokupakisha yokupakisha ye-pallet.

3. Ibhokisi lokubonisa langaphambiliubuchwepheshe bokupakisha esitsheni

I-pallet iyisitsha sohlobo lwefreyimu enamandla amakhulu futhi ifaneleka ngokukhethekile ukupakisha imikhiqizo esindayo enezakhiwo eziyinkimbinkimbi namaqoqo amakhulu. Eminye imikhiqizo inamaqoqo amakhulu kanye nokuma okuyinkimbinkimbi futhi ayikwazi ukupakishwa kuma-pallet. Isakhiwo sohlaka ngokuvamile senziwe ngensimbi, izinkuni noma ezinye izinto. Umsebenzi wayo ukulungisa nokuvikela izinto, kanye nokuhlinzeka ngezinto ezidingekayo ezisizayo zokuphakamisa, i-forklifting kanye nokupakishwa kwemikhiqizo ngemva kokuhlanganiswa. Lolu hlobo lwesakhiwo sohlaka lubizwa ngokuthi i-pallet, engagaywa kabusha futhi isetshenziswe kabusha isikhathi eside.

Isiqukathi yibhokisi lenzuzo elikhulu eliphelele kanye nesitsha esikhulu sokupakisha semikhiqizo yokupakisha yesiqukathi. Ngokuvamile ikhiqizwa futhi isetshenziswe ngokuhambisana nezindinganiso zamazwe ngamazwe. Ukuthuthwa kwesitsha kunezinzuzo ezingenakuqhathaniswa kunezinye izindlela zokuhamba futhi sekuyindlela eyinhloko yokuthutha impahla emhlabeni wonke.

I-ISO/TC104 Container Technical Committee ye-International Organisation for Standardization ichaza isiqukathi “njengesitsha esingasetshenziswa kabusha isikhathi eside futhi sinamandla anele; singadluliswa ngesikhathi sokuthutha ngaphandle kokuhambisa impahla esitsheni, singashintshwa ngokuqondile, singalayishwa ngokushesha futhi sithululwe, futhi singadluliswa ngokuqondile sisuka endaweni yokuhamba Kalula sidluliselwe kwezinye izinto zokuthutha kanye nevolumu ekahle yokuthutha, ukuthutha nevolumu. ngaphezu kuka-1m.” Ziningi izindlela zokuhlukanisa iziqukathi, futhi zihlukaniswa zibe iziqukathi ze-aluminium, iziqukathi zensimbi neziqukathi ze-fiberglass ngokwezinto zokwakha. . Ngokusho kwesakhiwo, zihlukaniswe ngeziqukathi zezinsika, iziqukathi ezigoqayo, iziqukathi ezinamagobolondo amancane kanye neziqukathi zefreyimu. Ngokusho kwenhloso, zihlukaniswe zibe iziqukathi ezijwayelekile neziqukathi ezikhethekile. Iziqukathi zenhloso ejwayelekile, okungukuthi, iziqukathi ezijwayelekile zempahla ezomile, ziyiziqukathi ezisetshenziswa kakhulu ezinezinga eliphezulu lokumiswa. Ngokuvamile zisetshenziselwa ukuthutha imikhiqizo yezimboni eqediwe noma amaphakheji angadingi ukulawulwa kwezinga lokushisa. Iziqukathi ezikhethekile ziyiziqukathi ezinezidingo ezikhethekile zamaphasela noma izimpahla ezithile, njengeziqukathi eziyinqwaba, izitsha ezivulekile, izitsha eziqandisiwe, izitsha ezifakwa umoya, izitsha ezifakwa umoya, izitsha ezivuleke ngokugcwele eziseceleni, izitsha zokubeka amapuleti, izitsha zamathangi neziqukathi ezibiyelwe. linda.

Ukupakishwa kwesitshaibhokisi lokubonisa langaphambiliubuchwepheshe ikakhulukazi buhlanganisa ukulungiswa kwepulani lokupakisha impahla, ukukhethwa kwemodi yokuthutha kanye nendlela yokunikezela ngempahla

njll. Ukuze uthole izidingo ezifanele, sicela ubheke izindinganiso zokuthutha iziqukathi.

Isikhathi sokuthumela: Mar-22-2024